|

| T-1 PVDF for fluorocarbon coating (DF-1) |

|

T-1 PVDF for (liquid) coating is solid powder, it can mixed with acrylic resin, additive,and become superior performance baking PVDF fluorocarbon coating. Compare with other grade of PVDF, T-1 is more suitable for stoving finish, baking light color coatings.

T-1 PVDF powder as raw materials, through mixtures, spray process, the fluorocarbon coatings have good mechanical strength, flexibility, good irradiation resistant, excellent adverse weather conditions resistant, and stability in wide temperature range.

T-1 PVDF technical data sheet |

Property |

Typical Values |

Standard |

Appearance |

White powder |

|

Odor |

None |

|

Purity |

99.5% |

|

Standard specific gravity |

1.74-1.77 |

ASTM D792,at 23/23℃ |

Melting point |

156-165℃ |

ASTM D3418,10℃/min |

Melt flow index |

0-2.0g/10min |

ASTM D1238,230℃,10kg |

Thermal decomposition temperature |

382-393℃ |

TGA,1%Wt.loss.Air |

Water absorption |

0.1% |

Karl Fischer |

Hegman fineness |

5.5 |

D1210,B |

|

Application and use method

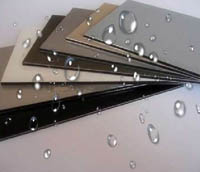

T-1 PVDF be widely used in coil coatings, curtain wall, skylight, roof, aluminium extrusion profiles, aluminium composite panel, composite board etc.

Use method: Roller coatings, Bruching, dipping, spraying , powder electrostatic spraying, it become coating film after baking.

PVDF coatings performance

Super weatherability, it can beused more than 20 years on outdoor weather.

Excellent temperature resistance, PVDF coatings can be long-time used in

-60℃-150℃.

PVDF coating standard

America AAMA 2605-98

P.R. China chemical industry standard HGT3793-2005

Packing

250kg/bag |

|